News

PLC Functions of Pellet Production Line

1) It can be logged in by operators with different identities.

When logging in the system, the operator has to choose an identity on the landing interface, shown as the picture (an example project in China, it can be written in multiple languages for your choice):

2) Real time monitoring

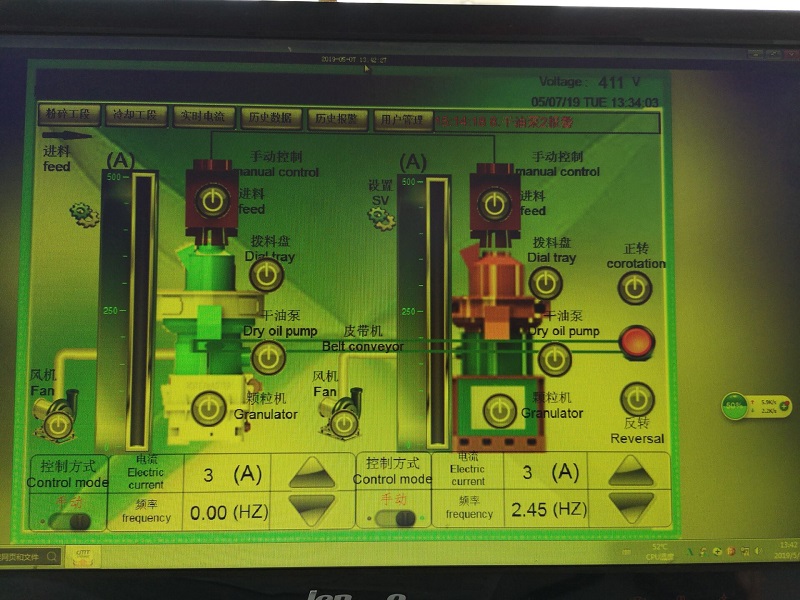

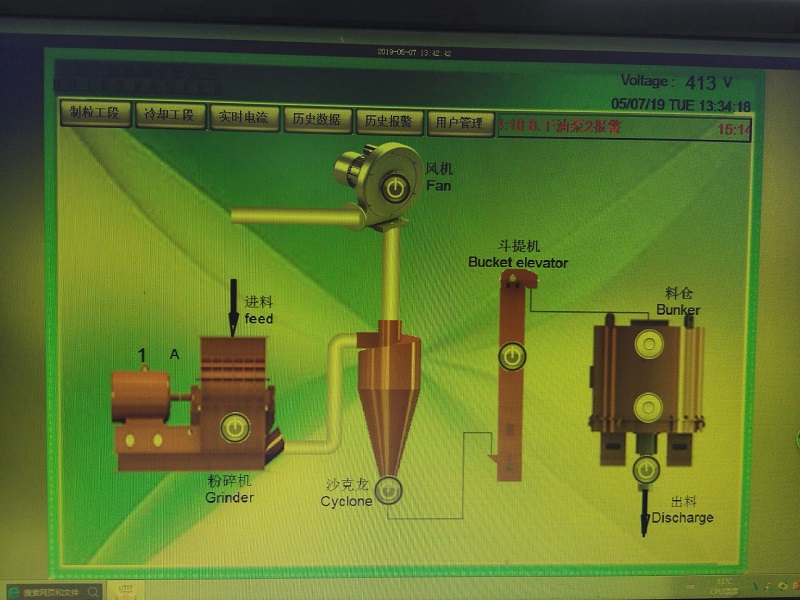

The first interface after logging in is the main interface where the real time monitoring over entire system can be conducted by clicking on the different functional buttons on the interface, as can be seen below:

3) Switching between manual / automatic operation button.

After ensuring the automatic production line runs normally, the operator can click the remote auto button to switch into the automatic operation. In the main interface, the operator can supervise all the processes of each functional sections and the entire dynamic production process of the production line from the feeding of raw materials to the pelletization of the pellets.

4) Remote hand control, flexible operation

When the starting or the stopping of a specific section of or the entire production line is needed under certain circumstance, the operator can press the "remote hand control button on the main interface, and then choose the corresponding functional button according to the requirements.

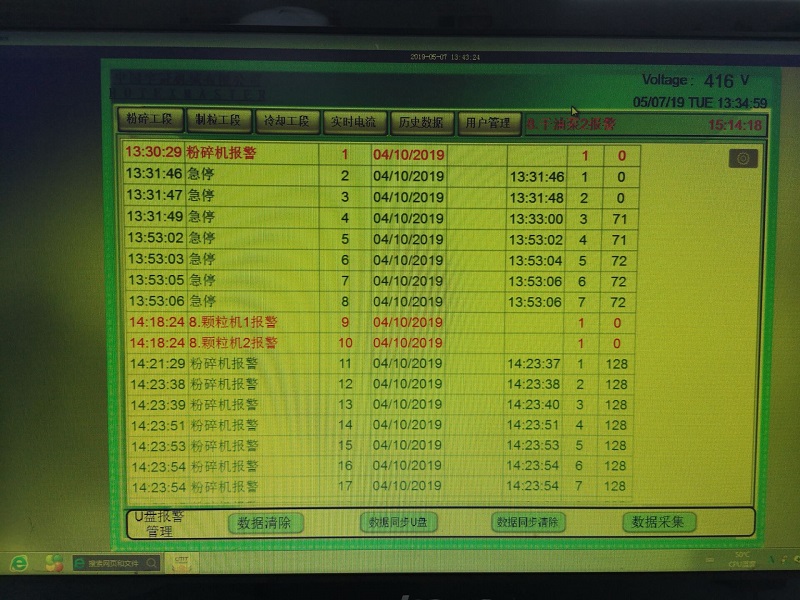

5)Alarm Check

Click on the " alarm check" button on the main interface, the system will switch into the alarm recording interface, where all the alarm information is recorded and analyzed by the host system,providing data support for the on-site technicians.

6) Visualized trend analysis

The trend analysis interface will be presented after clicking on the "trend analysis" button. On the trend analysis interface, the. system operational parameters will be presented in visualized diagram sand the trend of the system operational parameters can be observed clearly.

The YG-PLC Pellet Mill automatic control system adopts the advanced technology in the field, with independent intellectual property rights, accredited by Nanjing Municipal Transformation Projects of New and High-tech Achievements, winning a good reputation among clients.

7) Monitorable module

RReal-time monitoring of variable frequency feed in each section.

RCrushing section into and out of the production, real-time monitoring of output.

RReal-time detection of dryer feed and discharge port temperature, energy consumption, variable frequency fan Rair volume control, abnormal alarm.

RParticle machine inlet and outlet, bearing chamber temperature, energy consumption, production monitoring.

RAutomatic monitoring of the silo level.

RInverter monitoring and monitoring of each host.

Note: Modules can be added according to customer requirements.

8) Customer preparation

The computer hard disk storage needs to be 3000GB, which can retain all the data of the entire production line within one year.

It can also be remotely controlled via a smart phone, and a server is required to connect to the LAN.

9) Video Reference

https://youtu.be/vq9PTc4cczI

Categories

News

Contact Us

Contact: Bolida

Phone: 86-0531-67880768

Tel: 86-0531-67880768

E-mail: sales@rotexmaster.cn

Add: Dazhan Village, Zaoyuan Street, Zhangqiu District, Jinan City, Shandong Province, China.